Bernard Expands and Updates Clean Air Fume Extraction Gun Offering

BEECHER, Ill. November 16, 2017 — Bernard has introduced a new model to the Clean Air™ fume extraction gun family and has updated the entire Clean Air offering with a new look. A 300 amp MIG gun has been added to the Clean Air family, which allows users to reduce smoke at the source with an industrial-duty fume extraction gun that is comparable in size and weight to a regular welding gun. In addition, Bernard has changed the finish from chrome to black on all Clean Air fume extraction gun vacuum tubes and chambers. This aesthetic change has been made on all new guns, replacement vacuum tubes and replacement chambers.

The expansion of the Clean Air fume extraction gun offering provides more choices and greater flexibility for operations seeking to establish a cleaner, more compliant work environment. Clean Air fume extraction guns are also available in 400-, 500- and 600-amp models and can be used with solid and flux-cored wire. The guns are compatible with high performance consumables from Bernard, including Centerfire™, Quik Tip™ and TOUGH LOCK®, as well as the conventional liner or QUICK LOAD® liner. Users can make their selection and customize their Clean Air fume extraction gun when configuring their gun online.

All Clean Air fume extraction guns have a small vacuum chamber that provides good joint access and visibility, along with a 360-degree vacuum hose swivel on the rear of the handle that improves flexibility and reduces operator wrist fatigue. The guns are ideal for large weldment and confined space welding applications.

BEECHER, Ill. August 14, 2017 – Bernard and Tregaskiss will showcase its welding guns and consumables at FABTECH 2017 in Chicago, November 6 to 9, along with providing a variety of demonstrations. Both companies will share booth B23034 with Miller Electric Mfg. Co. and Hobart, where they will feature live welding demonstrations of Bernard semi-automatic and Tregaskiss robotic MIG guns with Miller power sources and robotic welding equipment using Hobart filler metals — offering visitors the chance to try a complete welding solution from the brands. In addition, representatives will provide demonstrations on how to repair, maintain and install option changes to the Bernard BTB semi-automatic air-cooled MIG guns, to illustrate the ease of maintenance or modification. The company plans to feature new products designed to improve quality, productivity and cost savings, and will have representatives available to answer product and technology questions.

WINDSOR, Ontario. June 5, 2017 — Tregaskiss announced the company is celebrating its 50th anniversary. Founded in 1967 by William Tregaskiss, a toolmaker from England, the company introduced its first semi-automatic MIG gun in 1972 to address the demanding welding needs of the automotive industry. Since then, the company has introduced the well-known TOUGH GUN® and TOUGH LOCK® brands, and today is known as an industry leader in the manufacturing of robotic MIG guns, peripherals and consumables. “We’re excited about this milestone and thankful to the people who have made our company what it is today,” says Diana Schneider, vice president/general manager, Tregaskiss. “From our dedicated employees who work hard to develop the best possible products to our customers and channel partners who continue to support us, everyone is critical to our success — we value these relationships.” Tregaskiss was family owned and operated until it was purchased by Illinois Tool Works (ITW) in 2007.

BEECHER, Ill., November 22, 2016 – Bernard has announced the expansion of handle options from six to seven choices for its BTB semi-automatic MIG gun line. Handle options now include the new C series straight handle, which provides all the benefits of the existing T series straight handle, plus additional ergonomic benefits such as a handle overmold and rear swivel — at no extra cost. Designed for maximum configuration flexibility and industrial-grade performance, Bernard BTB semi-automatic MIG guns provide users with options ranging from 200 to 600 amps with numerous cable length choices between 8 to 25 feet. The new C series straight handle is available for guns rated from 200 to 500 amps. By visiting the BTB MIG gun configurator, users can customize their gun with the C series straight handle or other handle options, choosing from three high performance consumables series — Centerfire™, TOUGH LOCK® or Quik Tip™ consumables — and multiple trigger options. Insight Limited™ triggers are an available option when selecting the new C series handle, and are designed specifically for use with power sources from Miller Electric Mfg. Co. that feature Insight Centerpoint™ welding information management systems. Users can also choose from 20 fixed and rotatable necks in various angles and lengths on any front handle style, and power cables are available in industrial-grade or steel monocoil to meet a variety of user needs. The BTB semi-automatic MIG guns feature a one-year warranty plus lifetime warranties on both the rear strain relief and the front handle. Additionally, BTB guns equipped with the new C series straight handle or a T series straight handle feature the double-life MIG gun system. When the front end of the gun becomes worn from routine use, this system allows users to simply flip the front end of the gun with back end for additional use.

WINDSOR, Ontario. Sept. 13, 2016 — A new online configurator from Tregaskiss makes it quick and easy to customize the company’s TOUGH GUN® TT3 reamer robotic nozzle cleaning stations to match the needs of their welding application. Users simply follow a series of steps to configure a reamer model, first selecting the V-block and cutter blade to match the outside diameter (OD) and bore of their robotic MIG gun nozzle. Users can then select from various add-ons, including a wire cutter, lubricator, air blast and/or filter/regulator. Tregaskiss also offers the option to choose accessories sold separately, such as a reamer stand, anti-spatter liquid and an anti-spatter multi-feed system. After choosing all desired components, the configurator provides a summary of the selections, along with a part number for the reamer. Users are given the option to request a quote for the reamer, download spec sheets or owner’s manuals, print the selection summary and part number, or contact Tregaskiss for more information. To help users save time, the online configurator incorporates a new reverse part number lookup function that provides a complete replacement parts list for their reamer based on an existing part number. The reamer is available for customization in both analog and Ethernet models. The analog TOUGH GUN TT3 reamer features improvements to the sprayer system, new plug and play replacement parts, and simplified internal wiring for reliable performance and ease of maintenance. The TOUGH GUN TT3E reamer offers the same high levels of durability, serviceability and repeatability and is enhanced with digital Ethernet communications for better integration into facilities’ digital controls infrastructure.

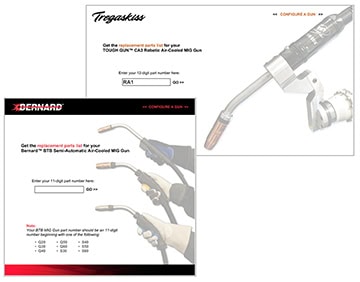

BEECHER, Ill./WINDSOR, Ontario. August 9, 2016 – Bernard and Tregaskiss have introduced a new reverse part number lookup function for their semi-automatic and robotic MIG gun online configurators — online tools that allow users to customize a MIG gun for their exact needs, by selecting amperage, neck style and angle, consumables and more. The new time-saving reverse part number lookup function provides users with the complete replacement parts list — from power pin to contact tip — for previously configured MIG guns, based on the existing part number. Reverse lookup information is available for the Bernard® BTB semi-automatic MIG guns and Clean Air fume extraction guns, along with Tregaskiss® TOUGH GUN® CA3 and TA3 robotic MIG guns. It is also available for the TOUGH GUN G2 series robotic MIG guns (both conventional and througharm styles) and features additional functionality for these products to simplify conversion to a TOUGH GUN CA3 or TA3 robotic MIG gun. Users of Tregaskiss robotic water-cooled MIG guns (600 amp) and TOUGH GUN TT3 reamers can also benefit from this reverse part number lookup function. To utilize the part number lookup function, users can visit Tregaskiss.com/ConfigureMyGun and follow the prompts on the home screens to enter an existing part number.

BEECHER, Ill./WINDSOR, Ontario. August 2, 2016 – Bernard and Tregaskiss will attend FABTECH 2016 in Las Vegas, November 16 to 18, where they will share booth N3733 with Miller Electric Mfg. Co. There, the companies will showcase the latest products for improving welding in the fabrication and manufacturing industries. Bernard will feature its semi-automatic MIG guns and consumables, while Tregaskiss will showcase its robotic MIG guns, peripherals and consumables — all designed to improve quality, productivity and cost-savings. Select products will be featured on Miller power sources and robotic welding equipment for static and live demonstrations. New products to be featured at the show, include: TOUGH GUN TT3E reamer — The new reamer from Tregaskiss has been enhanced with digital Ethernet communications to simplify integration into companies’ digital controls infrastructure, all at a lower cost. Remote monitoring capabilities allow companies to oversee and troubleshoot the I/O of reamer functioning in real time — without removing the reamer from the weld cell. TOUGH GUN reamer stand – Designed exclusively for Tregaskiss TOUGH GUN TT3 and TOUGH GUN TT3E reamer robotic nozzle cleaning stations, this durable new stand is customizable in heights ranging from 18 to 45 inches. A simplified design allows for lower pricing, while features such as precision- manufactured, reamer mounting hole pattern specific to the two reamer models eliminates potential issues associated with third-party stands. Quick, accurate installation is easy due to compatibility with both reamers’ quick-change base plate.

WINDSOR, Ontario. June 16, 2016 — Tregaskiss has announced the availability of its new TOUGH GUN® reamer stand, designed exclusively for its TOUGH GUN TT3 and TT3E reamer robotic nozzle cleaning stations. This fixed, durable stand can be ordered in custom heights ranging between 18 and 45 inches, and features a simplified design compared to previous models, allowing for lower pricing. The TOUGH GUN reamer stand features a bolt pattern that supports the use of the convenient quick-change base plate featured on all TOUGH GUN TT3 reamer models, as well as a precision-engineered hole pattern specific for mounting the TOUGH GUN TT3 reamer or the new TOUGH GUN TT3E reamer — a nozzle cleaning station enhanced with digital Ethernet communications for better integration into facilities’ digital controls infrastructure. In addition, the reamer stand includes a standardized 8.5- x 6.5-inch hole pattern for mounting the stand to the floor so users can easily swap stands between weld cell stations. These features allow for quick, accurate installation. The new reamer stand includes clamps and fasteners for optimal cable management along the stand and the hardware necessary for mounting a filter/regulator unit (sold separately).

WINDSOR, Ontario. April 26, 2016 — Tregaskiss has introduced its new TOUGH GUN® TT3E reamer, a robotic nozzle cleaning station enhanced by digital Ethernet communications to better integrate into companies’ digital controls infrastructure. The TOUGH GUN TT3E reamer can reduce integration costs by up to $1200 compared to analog reamer models by eliminating the need for an analog switch and reducing cabling requirements within the robotic weld cell. Plus, fewer components reduce potential failure points. The new reamer also offers remote monitoring capabilities, allowing companies to oversee and troubleshoot the I/O of each reamer function and its allowable parameters through the programmable logic controllers (PLC), all in real time and without the need to remove the unit from the weld cell. This feature, along with error diagnostic and recording capabilities minimize troubleshooting downtime and support greater productivity. Featuring discrete control, the TOUGH GUN TT3E reamer offers the flexibility to monitor and adjust all motions, along with insert recovery or fault control, further increasing productivity. In automatic mode, the reamer provides control over double-stroke, start-up dwell time and top-of-stroke dwell time. In the manual mode, there is control over the sequence and duration of each function by firing individual I/O. The TOUGH GUN TT3E reamer offers users the flexibility to operate the system as a switch to link robots with a single Ethernet port to an Ethernet welder or other peripherals. It also features a single wiring harness for all wire connections and improved wire labeling, minimizing the risk of wiring errors during routine maintenance and with it, unnecessary downtime. This new reamer offers the same high levels of durability, serviceability and repeatability as Tregaskiss’ popular TOUGH GUN TT3 reamer. A 3/4 horsepower lubricated air motor with gear reducer offers the high torque necessary for spatter removal, while operating at lower speeds to protect the spindle and cutter blade from excessive wear. Adding to this durability, the spindle has a rotating rod accuracy of 0.001 to 0.004 inch at its extended position, providing optimized, repeatable spatter removal. Additionally, external setup switches allow independent operation of the sprayer, clamp and spindle during manual setup, and the cutter blade lifts into position but does not spin when activated by the spindle setup switch. Momentary manual override switches further increase safety.

BEECHER, Ill./WINDSOR, Ontario. July 29, 2015 – Bernard and Tregaskiss have announced plans to attend FABTECH 2015 at McCormick Place in Chicago, November 9 to 12. To help companies improve productivity and quality, Bernard will showcase the latest in its semi-automatic MIG guns, fume extraction guns and consumables. Tregaskiss will feature its robotic MIG guns, peripherals and consumables. Both will share booth N14037 with Miller Electric Mfg. Co. and will feature select products on Miller power sources and robotic welding equipment for static and live demonstrations. Products to be on display from Bernard include: Tregaskiss will feature products at the show including:

WINDSOR, Ontario. July 16, 2015 — As a complement to the already reliable performance of the TOUGH GUN® TT3 reamer, Tregaskiss offers several accessories that are also designed to protect this peripheral. The TOUGH GUN reamer extends the life of robotic MIG guns and consumables by clearing the front end of spatter, helping to enhance productivity and improve weld quality in automated welding operations. Available accessories include: Lubricator: This dedicated motor lubricator is factory-set for optimal pneumatic oil lubrication and is ideal for damp environments. It can be ordered with a new TOUGH GUN TT3 reamer, which extends the Tregaskiss warranty from one year to three years, or retrofitted to an existing reamer. Filter / regulator: The filter cleans the air supply to the reamer, while also restricting debris from reaching the motor, resulting in less contamination and a longer reamer life. The regulator helps ensure the unit receives optimal air pressure. Spray containment unit: To improve air quality and help keep the weld cell cleaner, this unit captures anti-spatter overspray in its sealed basin, channeling it away from the unit to a convenient point of disposal, which can be shared among several Spray Containment units via an optional manifold. TOUGH GUN wire cutter: The wire cutter removes the ball-end of the welding wire to provide smooth arc starts and consistent wire stick-out, and can be used on a variety of wire types up to 1/16 inch in diameter. The wire cutter features a unique carbide cutter blade design with eight indexable cutting surfaces. Replacement cutter blades: These durable and accurate replacement cutting blades for the TOUGH GUN TT3 reamer feature a twin flute design for improved cutting and cleaning performance, all at a competitive price. They are made from harder, stronger material to increase resistance against breaking, snapping, chipping or cracking, and are designed to fit perfectly with TOUGH LOCK® consumables. Tregaskiss v-block: Compatible with Tregaskiss consumables and competitive brands, this four-sided v-block ensures that the cutter is concentric with the consumables and nozzle bore so that the reamer can effectively clear spatter. Tregaskiss offers five available v-block options when users configure a new TOUGH GUN TT3 reamer.

WINDSOR, Ontario. June 9, 2015 — Tregaskiss has announced the availability of its new Automation Catalog. Featuring the most up-to-date information on the company’s robotic MIG guns, consumables and peripherals, the catalog has a fresh new look and easy-to-read format. The 22-page, full-color Automation Catalog includes information about the new TOUGH GUN® CA3 and TOUGH GUN TA3 robotic air-cooled MIG guns, including convenient configurator spreads. These pages reflect the online configurators offered by Tregaskiss, which allow users to customize a robotic MIG gun for their exact needs based on amperage, neck and cable styles, power pin, gun mount and more. The catalog also features a new foldout consumables reference chart that provides technical and compatibility information for popular nozzles, retaining heads and contact tips, along with details about TOUGH LOCK® consumables and other Tregaskiss consumable brands. Other new additions to the Automation Catalog include information on:

WINDSOR, Ontario. May 4, 2015 — A Tregaskiss-sponsored robotics team from Vincent Massey Secondary School of Windsor, Ontario, Canada, attended the FIRST Robotics World Championship in St. Louis on April 22 — a first-time appearance for the students at a world-level competition. The team, which consisted of 40 students in grades 9 to 12, competed against the world’s best robotics teams, placing 44th out of 77 in their division (there were 600 teams total), and gaining valuable experience to take into competitions in 2016. Over 40,000 spectators attended the event. “The trip was such a positive experience for the students and the teachers/mentors, and we appreciate all the support we received along the way,” said Sandra Chappus, robotics team mentor. “The students and the robot performed at their personal bests, so everyone is quite pleased. We’re already looking to learn new technologies to take into competition next year.” Among those new technologies is pneumatics, a feature that a top-ranked team at the competition sought the Vincent Massey teams help with during the competition. Currently, the team is focused on mechanical, electrical, business/media and programming facets. According to Tregaskiss Director of Operations Darren Grey, the company plans to continue its sponsorship of Windsor-area robotics teams in the future, and many employees have expressed an interest in mentoring students as they prepare their robots for competition next year. “We consider programs like these to be an important investment in the students’ futures,” Grey said. “Tregaskiss is a natural fit to support automation technology and we are proud to be able to help.”

WINDSOR, Ontario. April 16, 2015 — Tregaskiss recently partnered with Vincent Massey Secondary School of Windsor, Ontario, Canada to sponsor their robotics team for the Windsor-Essex Great Lakes Regional FIRST Robotics tournament on April 2-3. The event featured 48 teams totaling more than 1,000 students. The Vincent Massey Robotics Team qualified for the finals, advancing the 40 students on the team (grades 9 to 12) to the FIRST Robotics World Championship in St. Louis on April 22, where Tregaskiss will also offer its sponsorship support. “Our students are thrilled to have a chance to compete at such a high level after only the second year as a team,” says Sandra Chappus, mentor for the Vincent Massey Robotics Team. “The students’ talent is definitely matched by their enthusiasm and they have exceeded their own expectations going into the FIRST event. We are thankful to all of our sponsors, including Tregaskiss, for their help. Without that support, the students wouldn’t have such great opportunities.” “The FIRST Robotics competition allows students to immerse themselves in an initiative that mirrors industry in the real world,” adds Darren Grey, director of operations at Tregaskiss. “Within a short timeframe and with a limited budget, they are tasked with designing and manufacturing a working robot to compete against teams from across the US and Canada. We consider our sponsorship an important investment in these students’ futures — they are aspiring to be the engineers, technologists and scientists of tomorrow.” The Windsor-Essex Great Lakes Regional FIRST Robotics tournament consisted of robots competing to stack totes and recycling bins and maneuver pool noodles. Students spent six weeks building their robot and coding it for the task. The team is broken into four divisions — mechanical, electrical, business/media and programming — allowing students to focus their strengths on executing the task.

Bernard and Tregaskiss to Feature Gun Repair/Maintenance Demos at FABTECH 2017

Bernard and Tregaskiss to Feature Gun Repair/Maintenance Demos at FABTECH 2017

Tregaskiss Celebrates 50th Anniversary

Tregaskiss Celebrates 50th Anniversary

Bernard Adds to Handle Options for BTB Semi-Automatic MIG Guns

Bernard Adds to Handle Options for BTB Semi-Automatic MIG Guns

Tregaskiss Offers Online Configurator for Robotic Nozzle Cleaning Stations

Tregaskiss Offers Online Configurator for Robotic Nozzle Cleaning Stations

New Reverse Part Number Lookup Function for Online MIG Gun Configurators Saves Time

New Reverse Part Number Lookup Function for Online MIG Gun Configurators Saves Time

Bernard and Tregaskiss to Attend FABTECH 2016

Bernard and Tregaskiss to Attend FABTECH 2016

New TOUGH GUN Reamer Stand Offers Customizable Height and Quick Installation at a Lower Cost

New TOUGH GUN Reamer Stand Offers Customizable Height and Quick Installation at a Lower Cost

New Robotic Nozzle Cleaning Station Reduces Integration Costs, Helps Increase Productivity

New Robotic Nozzle Cleaning Station Reduces Integration Costs, Helps Increase Productivity

Bernard and Tregaskiss to Showcase Products at FABTECH 2015 in Chicago

Bernard and Tregaskiss to Showcase Products at FABTECH 2015 in Chicago

Accessories from Tregaskiss Extend Life of Popular TOUGH GUN TT3 Reamer, Complement Performance

Accessories from Tregaskiss Extend Life of Popular TOUGH GUN TT3 Reamer, Complement Performance

New Automation Catalog Available from Tregaskiss

New Automation Catalog Available from Tregaskiss

Tregaskiss-Sponsored FIRST Robotics Team Attends World Competition

Tregaskiss-Sponsored FIRST Robotics Team Attends World Competition

Tregaskiss Sponsors Winning FIRST Robotics Team Headed to World Competition

Tregaskiss Sponsors Winning FIRST Robotics Team Headed to World Competition